for advanced pre-treatment

for advanced pre-treatment

Process-mechanisms

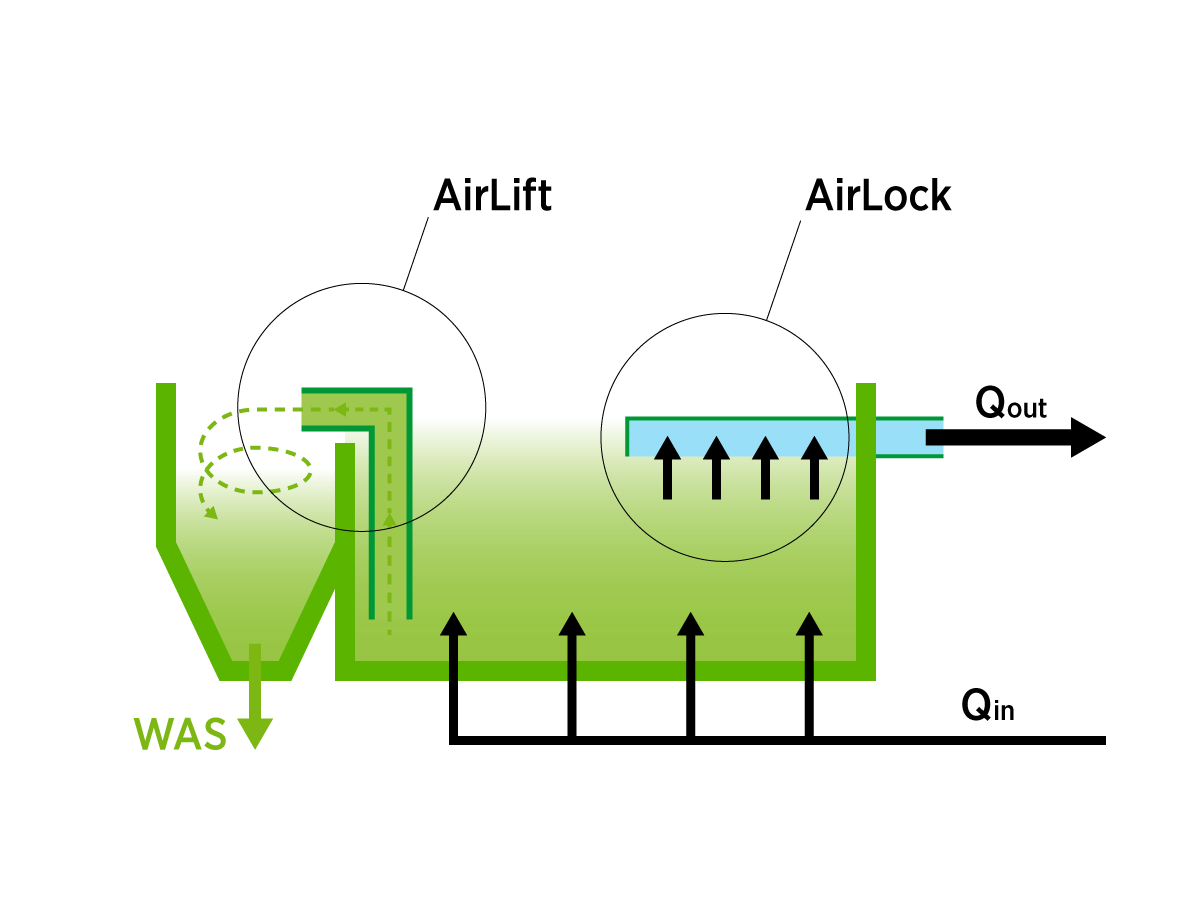

The brand ‚AAA‘ (Triple-A) stands for ‚Alternating Activated Adsorbtion‘. In conventional primary clarifiers purely physics is employed for settling particulate matter with an overall removal of organic matter by ca. 1/3. AAA applies a flow-through sludge blanket to maximize redirection of organic carbon to anaerobic digestion, improving the energy balance of the plant. It represents a compact pre-treatment unit that integrates all features of an A-stage in a dual-tank-configuration – biomass activation, biomass recycling, sludge wasting and waste sludge thickening, well suited to retrofit existing primaries at a hydraulic retention time of ca. 2 hours. Operational simplicity is the principle – the process cycle is fully air-driven without any mixers or pumps.

The process goals are:

- Off-load the plant, capacity increase

- Removal of ca. 2/3 of COD and ca. 1/3 of N and P

- Reduced aeration demand at increased methane yield – energy positive plant

- Integrated thickening to ca. 5% solids for direct feed to digesters

- Less cake-solids disposal due to high primary/secondary sludge ratio of ca. 0.75

Operational results

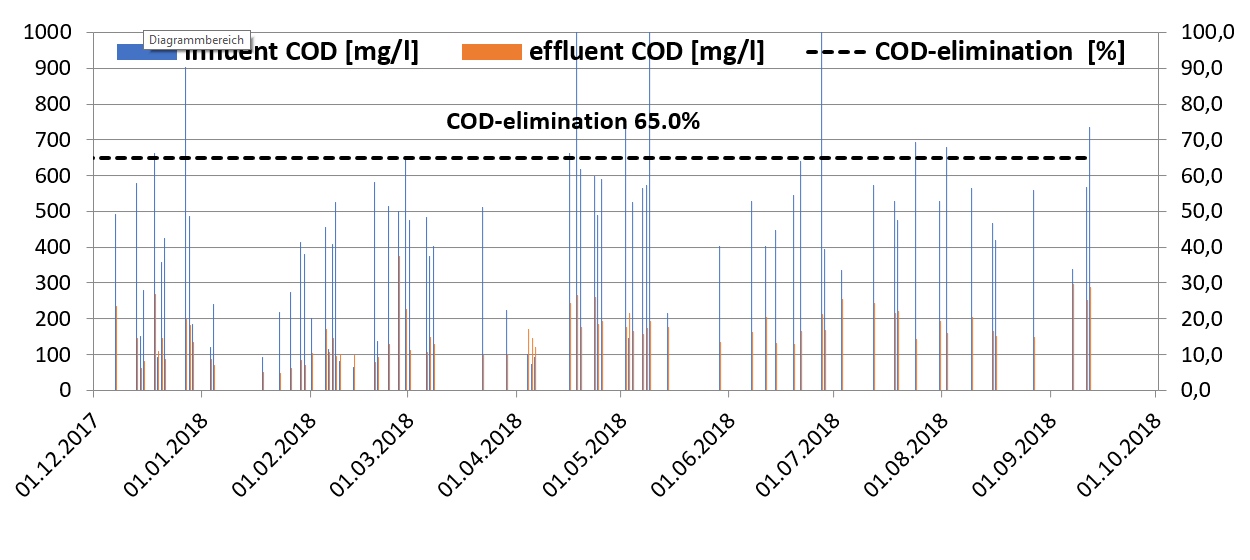

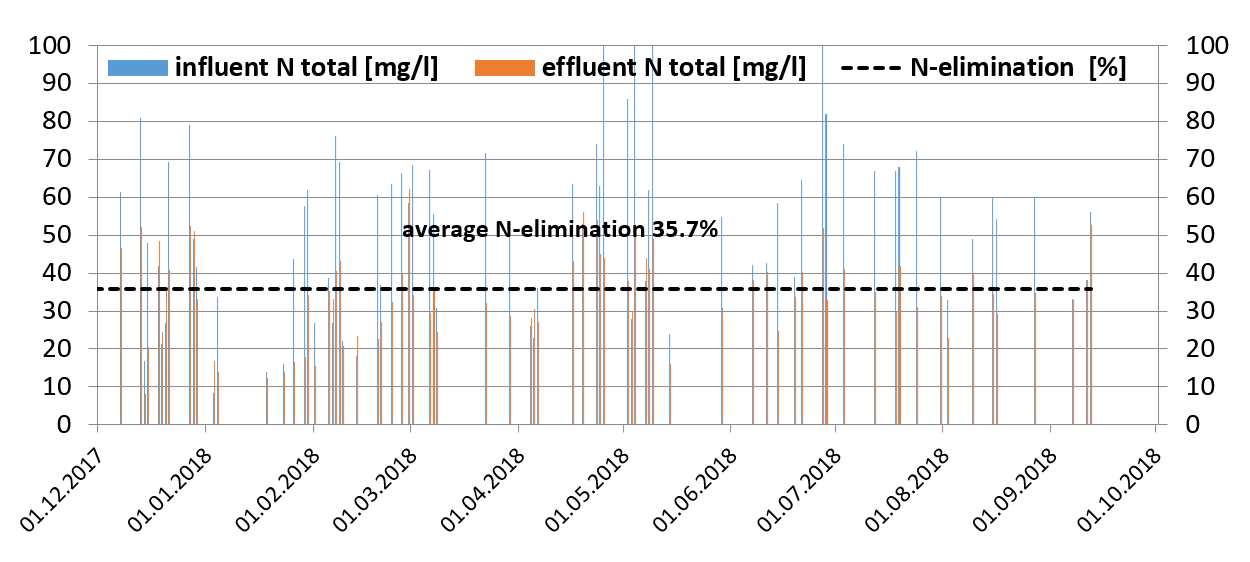

The WWTP in Germany (46000 PE) is a brownfield implementation of AAA, retrofitting two existing tanks. The system reached an average COD elimination of 66% and an average phosphorus elimination of 43%. The total nitrogen elimination is shown below, with average elimination rates of 36%.

Process-implementation

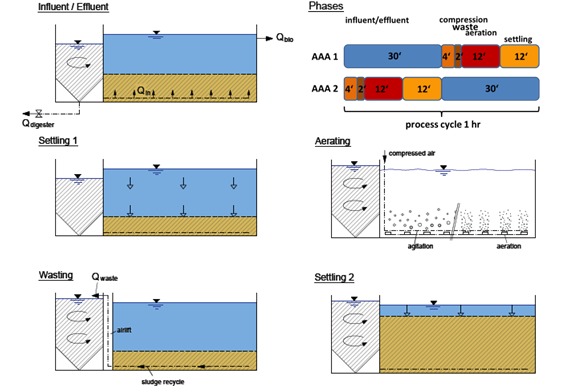

The system is operated typically in process cycles of 1 hour (see below). Each cycle consists of five phases: inflow/outflow (30min), compression, wasting, aeration and settling (as shown below). Whereas the outflow is driven by the inflow, all other processes are air-driven (aeration & mixing, air-lift wasting, air-lock-decanting). Aeration is oxygen controlled at a standard set-point of 1 mg/L DO, the duration of sludge wasting is depending on the actual solids content in the activation/settling tank and automatically adjusted based on online TS-measurements.

AAA can be implemented at greenfield and brownfield, small scale and large scale. The pictures below show the AAA container configuration and the construction works for the conversion of the sludge-hopper-zones of existing primary clarifiers to the AAA thickeners in Italy.

![2018-07-24-15_45_18-[1]-Laser–&-Luftbildatlas-Tirol Strass Zillertal](http://newportwater.tech/wp-content/plugins/revslider/public/assets/assets/dummy.png)