system for biomass densification

system for biomass densification

Process-mechanisms

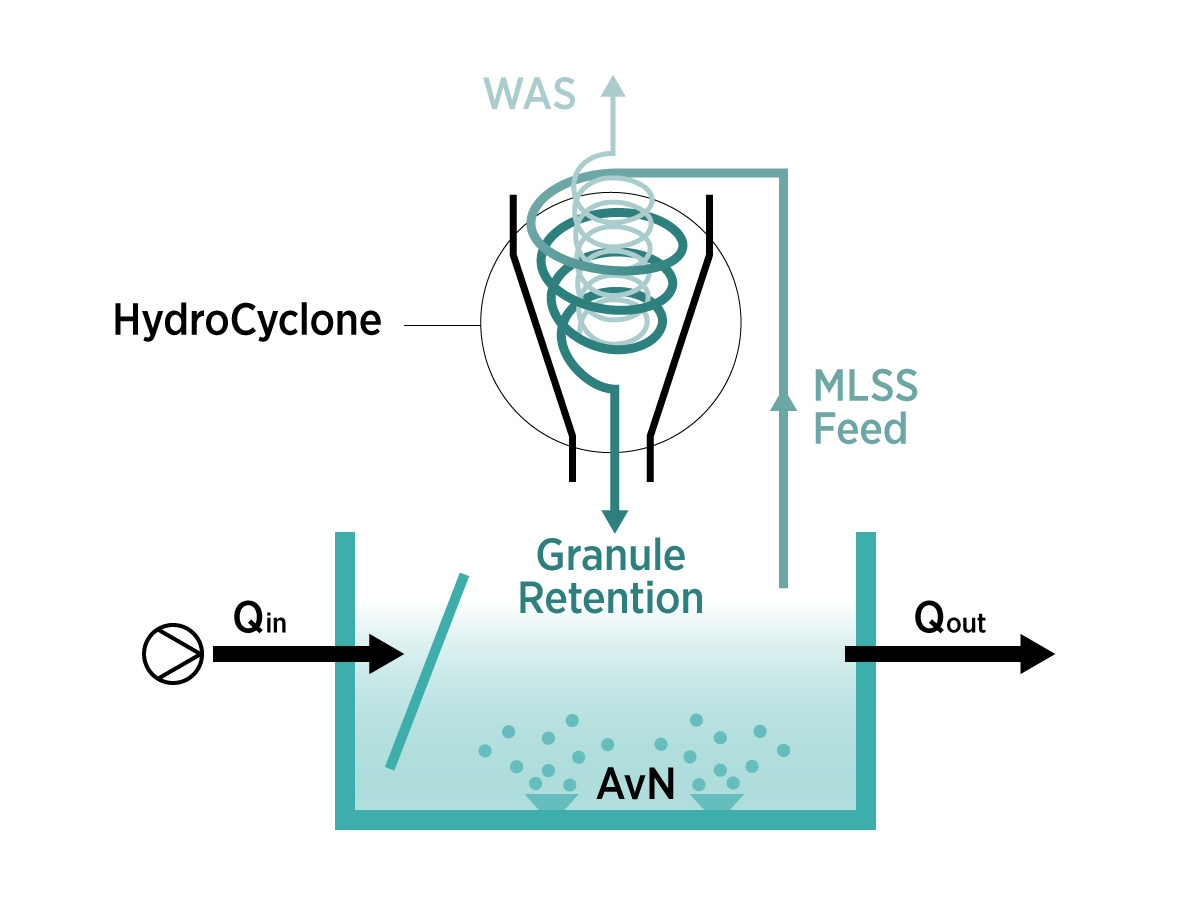

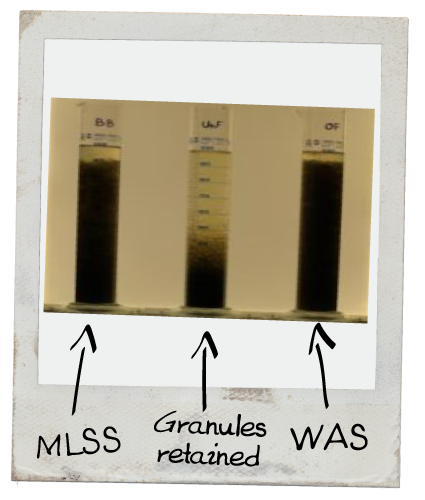

The brand ‚inDENSE‘ stands for ‚Process intensification by densified biomass‘. The settling properties of the biomass are the base for process design and higher settling rates reduce tank volumes or increase plant capacity, respectively. For the inDENSE-process hydro-cyclones are applied to separate out the light and fluffy sludge fraction which is fed to waste-sludge processing. The sludge-fraction in the cyclone under-flow contains denser biomass with a higher portion of Bio-P organisms. These Phosphorus Accumulating Organisms (PAO) grow preferentially under anaerobic niche-conditions in densified biomass and contain poly-phosphate-cores which add weight for an efficient selection process.

The process goals are:

- Improve sludge settling performance, prevent solids wash-out

- Allow for higher mixed liquor concentrations, capacity increase

- Enhance or stabilize biological P-removal

Operational results

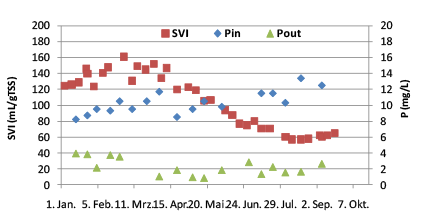

Within the operational period the selection and retention of densified biomass allows a reduction or stabilization of the sludge-volume-index (SVI). At the same time an interaction between settling-properties and Bio-P-activity can be observed.

The BIOCOS-inDENSE demonstration plant in Soyen (Germany) combines the BIOCOS cyclic activated sludge process without mechanical shear including an anaerobic selector with inDENSE granule-retention. Over a transition period of about half a year the measured SVI dropped from initially 140 (see figure: cyclone installation 17th of February) down to ca. 60 ml/g while the P-removal efficiency increased from ca. 60 to more than 80 %.

Process-implementation

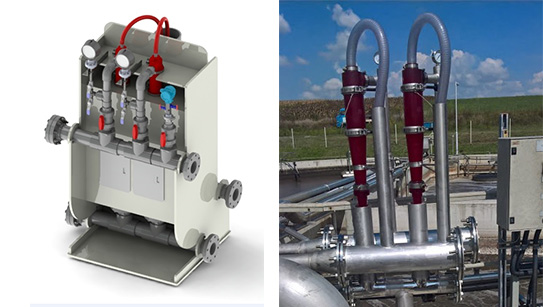

Hydro-cyclones are applied to achieve the described selection performance (figure: inDENSE-cyclone-skids manufactured out of plastic left vs stainless-steel right). These cyclones are fed with mixed liquor or recycled sludge at an operating pressure range of 2.0 to 2.5 bar. Driven by centrifugal forces ca. 10-20% of the feed-flow and ca. 1/3 of the mass-flux are separated out in the cyclone under-flow and recycled to the treatment process. To support the physical selection, a biological selection is provided under anaerobic conditions and high substrate gradients in a defined selector zone. This biomass is retained and enriched in the system by the hydro-cyclone, while the light sludge-fraction gets wasted.

This way inDENSE allows intensified usage of tankage, decreasing the volume requirement for green-field plants or increasing capacity of existing plants, respectively. Additionally, inDENSE is applied to prevent solids wash-out and bulking issues.

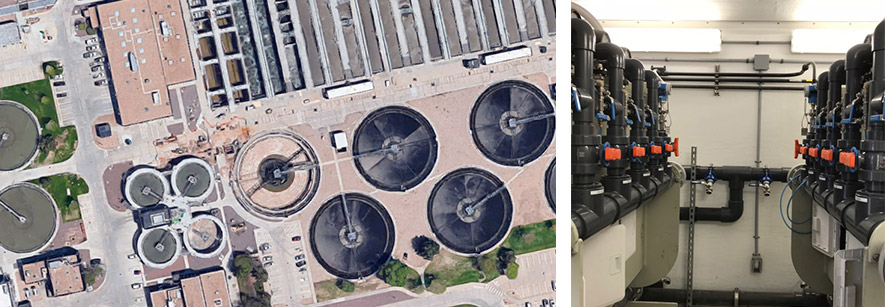

So far inDENSE® has been successfully implemented at several plants, among these the large installation in Colorado is going to start up (see photo).