sidestream deammonification

sidestream deammonification

Process-mechanisms

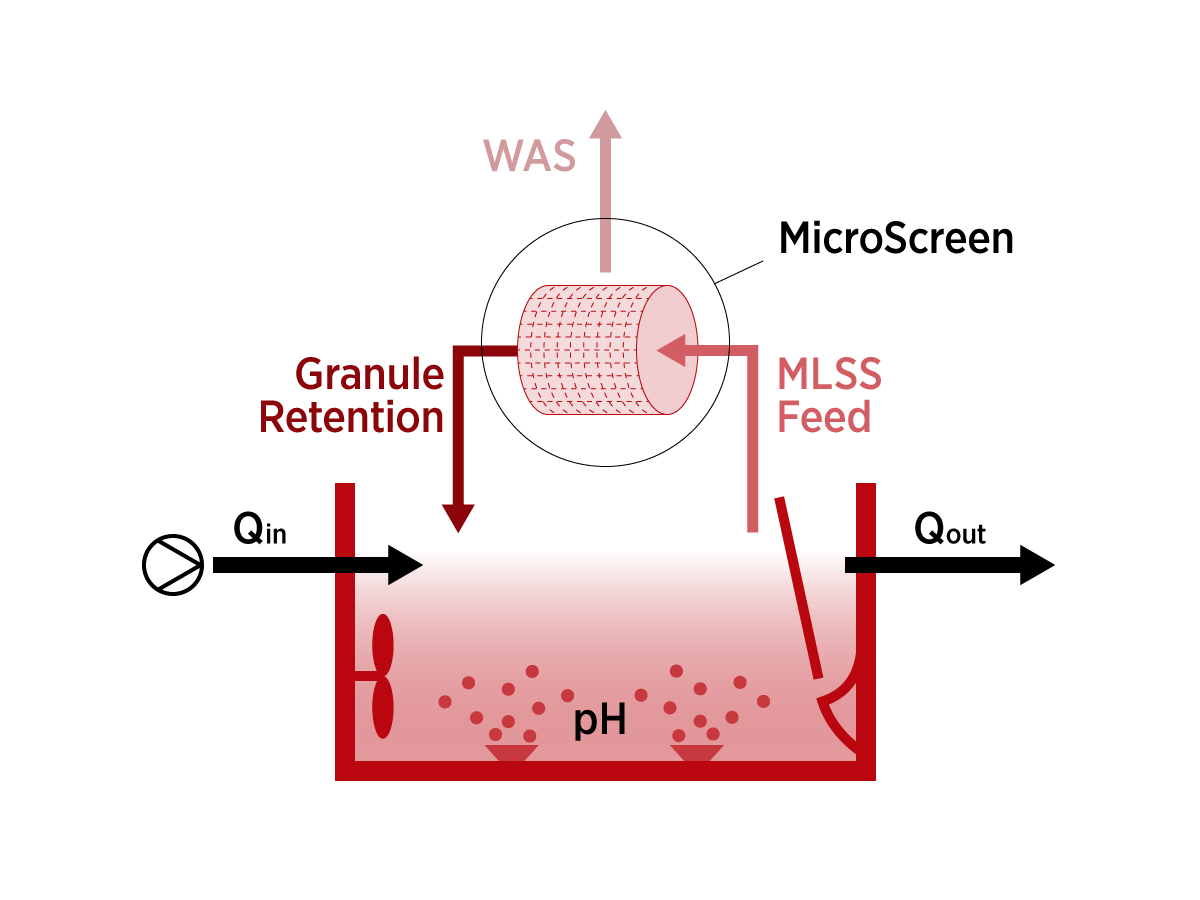

The brand ‚DEMON‘ stands for ‚Deammonification‘. The combination of aerobic and anaerobic ammonia conversion in a single reactor allows energy efficient nitrogen removal from high-strength ammonia wastewater. The core features of DEMON are the pH-controlled aeration to maintain the balance between aerobic and anaerobic conditions and the biomass selection and retention using micro screens. At municipal wastewater treatment with anaerobic digestion, DEMON targets the elimination of the nitrogen reject load from sludge dewatering liquors (ca. 20% of the total N-load). DEMON facilitates energy-positive whole plant concepts with efficient primary carbon removal where low C/N ratios are to be expected.

The process goals are

- Elimination of side-stream return load from digesters in small foot-print

- Low energy demand of ca. 1.2 kWh/kgN and no carbon requirement

- Process stability due to reliable aeration control and anammox-retention

Operational results

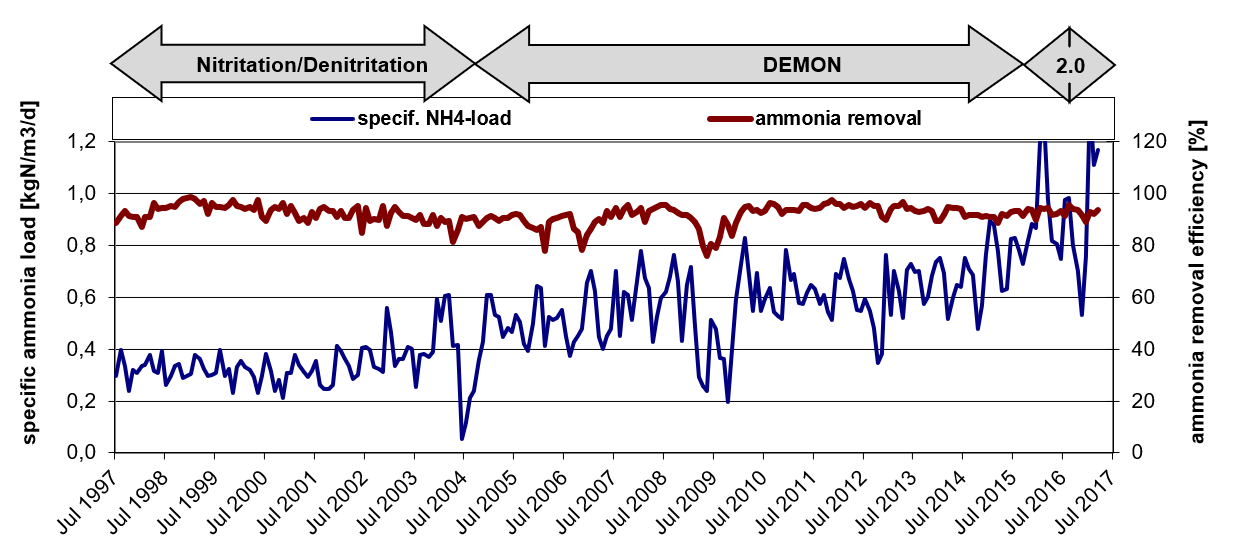

Since the invention of the process more than a decade ago, the process has been up-graded from DEMON 1.0 to DEMON 2.0: replacing hydro cyclones by micro screens for biomass selection and changing from SBR to continuous operation. The figure below from the Strass WWTP (Austria) shows the evolution of the treatment performance reflecting this process optimization. The success is evident: the loading rates could be increased from 0.5 to ca. 1.2 kg NH4-N/m3/d at a stable ammonia removal rate of more than 90%.

Process-implementation

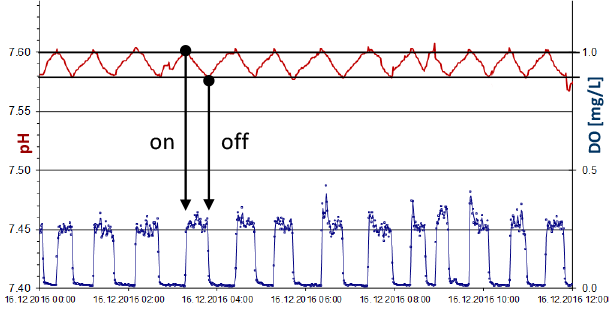

The DEMON reactor has an intermittent aeration system (pH-controlled; see graph below) to provide enough oxygen to convert about 50% of the incoming ammonia to nitrite. The produced nitrite is then used by anammox bacteria to oxidize the remaining ammonia to nitrogen gas. Since the anammox bacteria are slowly growing, the anammox granules are enriched in the system by a micro screen (see photo below), providing sludge retention over 50 days (vs. ca. 5 d for AOB). The treated effluent is decanted from the reactor via a baffle wall after sedimentation of the biomass.

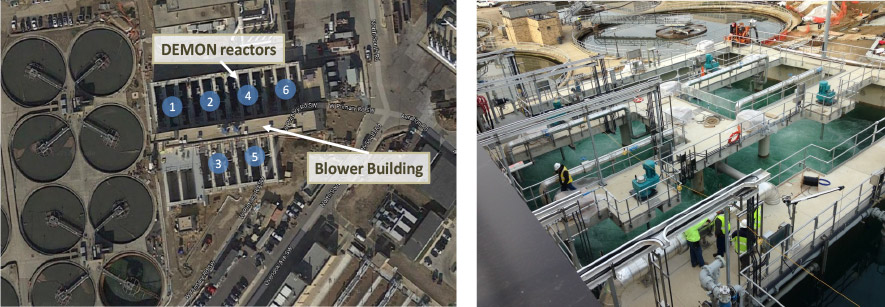

With more than 80 full scale implementation worldwide, DEMON is the market leader for side stream ammonia removal. The largest deammonification plant designed for ca. 12000 kgN/d has just recently started up at Blue Plains WWTP, Washington DC (see photos below). One specialty of this system is that it has to treat liquors from a thermal-hydrolysis digestion system (THP), which has a difficult and highly concentrated organic matrix. Another special implementation is located in the Netherlands, where DEMON is combined with a phosphorus recovery system at the same side-stream.